- PCB Fab

- Etching

- Exposure Machine

- Drilling Machine-Schmoll

- PTH Line

- Solderability Preservative

- Automatic Lamination

- Roll To Roll

- Inner Brown Oxide Line

- CNC Routing Machine

- Laser Direct Imaging

- Immersion Line

- Pre-Treatment

- PCB Assembly

- Automatic Loader

- Screen Printer

- High Speed Chips Mounter

- Multifunction IC Mounter

- Reflow

- Automatic Unloader

- BGA Rework Machine

- Electron Microscope

- Bake Oven

- Oven Temperature Tester

- Components

- Resistance

- Capacitance

- Inductance

- MOS

- MCU/ICS

- DC/DC

- Relays

- Module

- Others

- PCB Design

- AOI

- AOI Inspection

- X-Ray

- X-Ray

- Wave Soldering

- Wave Soldering

- ICT

- ICT

- Anti-Corrosion Paint

- Anti-Corrosion Paint

- Fixture Custom

- Fixture Custom

- LCD Screen Custormization

- LCD Screen Custormization

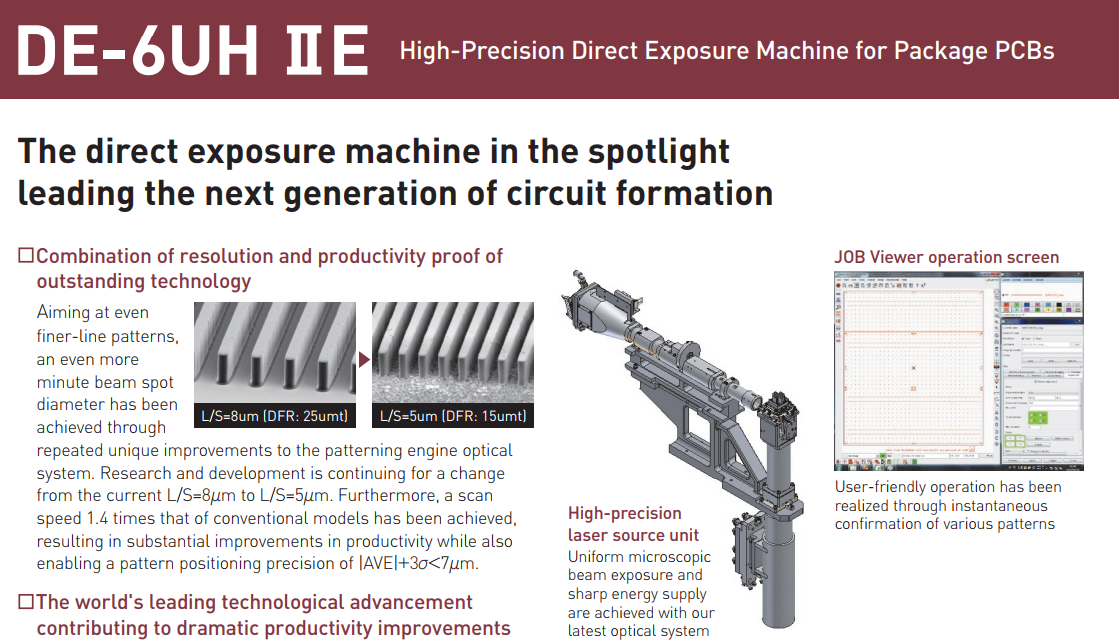

Auto Exposure System

Specification : Feature

1. High alignment accuracy: Alignment accuracy 3ơ < 10 µm

2. Made of SUS material

3. Load conveyor Roller use SUS polishing to ensure panel alignment quality

4. Aside alignment use weighting method to ensure the thin panel is not arched.

5. High resolution exposure frame design.

6. Collimating light used low energy consumption 5kw lamp

7. Double-sided exposure at the same time

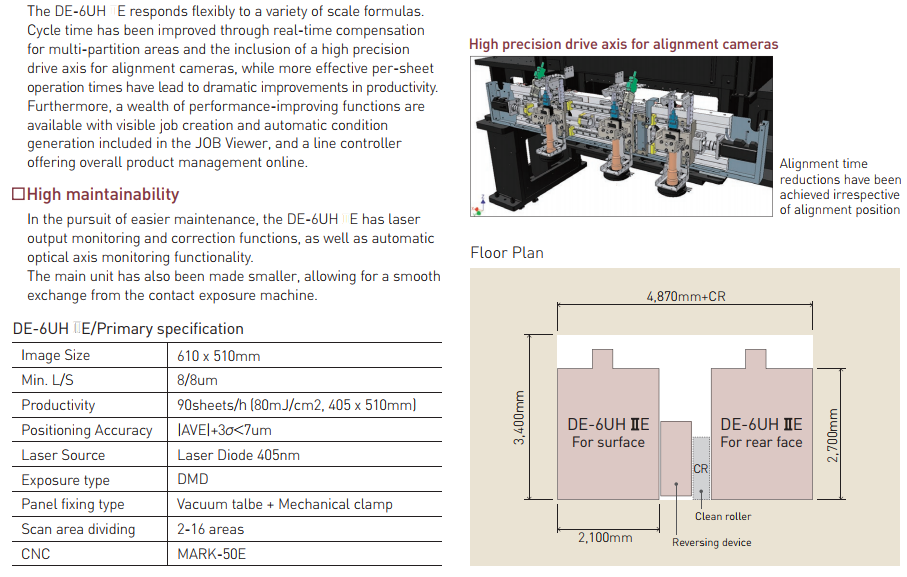

Specification : Feature

1. High alignment accuracy: Alignment accuracy 3ơ < 10 µm

2. Load conveyor roller use SUS polishing and driven by non-contact magnetic rings design.

3. Panel transfer structure to strengthen stability.

4. Extension type CCD vision and backlight module to increase the maximum panel utilization.

5. High resolution exposure frame design.

6. Using new type alignment algorithm to ensure sharing film error.

7. Scattered light used low energy consumption 5kw lamp.