- PCB Fab

- Etching

- Exposure Machine

- Drilling Machine-Schmoll

- PTH Line

- Solderability Preservative

- Automatic Lamination

- Roll To Roll

- Inner Brown Oxide Line

- CNC Routing Machine

- Laser Direct Imaging

- Immersion Line

- Pre-Treatment

- PCB Assembly

- Automatic Loader

- Screen Printer

- High Speed Chips Mounter

- Multifunction IC Mounter

- Reflow

- Automatic Unloader

- BGA Rework Machine

- Electron Microscope

- Bake Oven

- Oven Temperature Tester

- Components

- Resistance

- Capacitance

- Inductance

- MOS

- MCU/ICS

- DC/DC

- Relays

- Module

- Others

- PCB Design

- AOI

- AOI Inspection

- X-Ray

- X-Ray

- Wave Soldering

- Wave Soldering

- ICT

- ICT

- Anti-Corrosion Paint

- Anti-Corrosion Paint

- Fixture Custom

- Fixture Custom

- LCD Screen Custormization

- LCD Screen Custormization

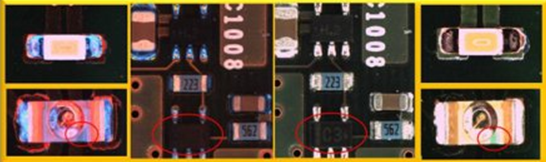

Each of our SMT production lines are equipped with AOI devices, to in-line mode, on the end of the production line, this is our standard, and not the option to all of our products after PCBA, all were examined by AOI.

2D/3D In-Line AOI,3D Inspection Technology in the SMT line.With the unique combination of 2D inspection and 3D measurement with only one head, this system achieves the highest productivity and ultimate inspection performance, and false calls are avoided.

With the 2D inspection, higher inspection speed, script and polarity detection are accomplished. The 3D measurement provides exact height and volume data.

The AOI utilizes a high resolution digital 15 MP camera technology with telecentric lens and optional four 10 MP side cameras (Side-Viewer®) for 3D inspection. This technology provides unique inspection performance and surpassing inspection speeds. The side cameras offer a spacial test and provide valuable information for a secure and reliable detection of side defects. Also, the check of complex components becomes a piece of cake.

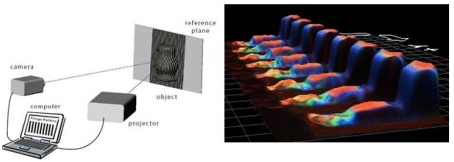

The 3D check takes place with Multi-Frequency analysis that also is used in 3D solder paste inspection systems. This technology offers full 3D measurement of height, area, tilt, lift, etc. A projector projects grid patterns on the area that has to be measured. The camera saves the image and transfers the data to the machine. Subsequently, the software displays the measured, realistic 3D image.

All AOI systems with a minimum resolution of 10 MP are furthermore standard equipped with the new 6 layer light system (RGB plus yellow light). This technology enables a full inspection of solder deposits and an enhanced detection of lifted leads.

|

|

|

RGB LED |

White LED |

| -Identify solder with three colours | -Solder inspection by binarizing |

| -Inspect component with distorted imge | -Component inspection with real image |