- PCB Fab

- Etching

- Exposure Machine

- Drilling Machine-Schmoll

- PTH Line

- Solderability Preservative

- Automatic Lamination

- Roll To Roll

- Inner Brown Oxide Line

- CNC Routing Machine

- Laser Direct Imaging

- Immersion Line

- Pre-Treatment

- PCB Assembly

- Automatic Loader

- Screen Printer

- High Speed Chips Mounter

- Multifunction IC Mounter

- Reflow

- Automatic Unloader

- BGA Rework Machine

- Electron Microscope

- Bake Oven

- Oven Temperature Tester

- Components

- Resistance

- Capacitance

- Inductance

- MOS

- MCU/ICS

- DC/DC

- Relays

- Module

- Others

- PCB Design

- AOI

- AOI Inspection

- X-Ray

- X-Ray

- Wave Soldering

- Wave Soldering

- ICT

- ICT

- Anti-Corrosion Paint

- Anti-Corrosion Paint

- Fixture Custom

- Fixture Custom

- LCD Screen Custormization

- LCD Screen Custormization

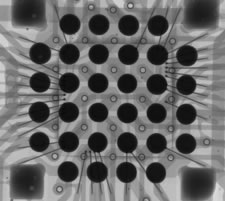

Realtime X-Ray Imaging

Non-destructive x-ray analysis, in real time, detecting and creating an immediate and thorough analysis of complex structures of varying densities. Our equipment enables us to identify and diagnose submicron defects, void percentage, solder sphere formation, and wire sweeping. This particular test gives the user freedom to enhance image quality and obtain distance and diameter measurements of a component.

This system also allows for single layer inspection of electronic components without the need to remove them from protective packaging; we are able to inspect without disrupting the original factory seal.

Information Obtained

Printed Circuit Boards

Solder joint formation

Metallization defects

Ball Grid Arrays

Solder formation and voiding

Die attach

Ceramic, Metal and Plastic Packages

Foreign material

Die attach

Bond wire sweep

Opaque particles

Energy-Dispersive X-Ray Spectroscopy

Energy-dispersive X-ray spectroscopy (EDS or EDX) is an analytical technique used for the elemental analysis or chemical characterization of a sample. It relies on the investigation of an interaction of some source of X-ray excitation and a sample. Its characterization capabilities are due in large part to the fundamental principle that each element has a unique atomic structure allowing unique set of peaks on its X-ray spectrum. To stimulate the emission of characteristic X-rays from a specimen, a high-energy beam of charged particles such as electrons or protons or a beam of X-rays, is focused into the sample being studied. At rest, an atom within the sample contains ground state (or unexcited) electrons in discrete energy levels or electron shells bound to the nucleus. The incident beam may excite an electron in an inner shell, ejecting it from the shell while creating an electron hole where the electron was. An electron from an outer, higher-energy shell then fills the hole, and the difference in energy between the higher-energy shell and the lower energy shell may be released in the form of an X-ray. The number and energy of the X-rays emitted from a specimen can be measured by an energy-dispersive spectrometer. As the energy of the X-rays are characteristic of the difference in energy between the two shells, and of the atomic structure of the element from which they were emitted, this allows the elemental composition of the specimen to be measured. While other X-Ray systems can determine the material, the EDX will perform a visual example. By analyzing and colorizing what is in view, the technician can obtain a photograph of the actual composition. This is important when identifying suspect components as many of the materials in blacktopping are of a different material composition on the surface versus the underlying layers below.

X-Ray CT Scanning & Digital Radiograpy

X-ray computed tomography scanning, or X-ray CT scanning, has proven to be a very powerful tool in the field of non-destructive testing. obtain highly detailed 3D images of the internal components of materials and products, thus eliminating the need for costly and time-consuming destructive inspection.